- The Company

- Innovation

- Products

- Certifications

- News & Exhibition

- Work with us

- Contact us

- Azienda

- Innovazione

- Prodotti

- Certificazioni

- News & Exhibition

- Work with us

- Contact us

Italiano

English

Stainless Steel

Condensing Heat Exchanger

Stainless Steel

Condensing Heat Exchanger

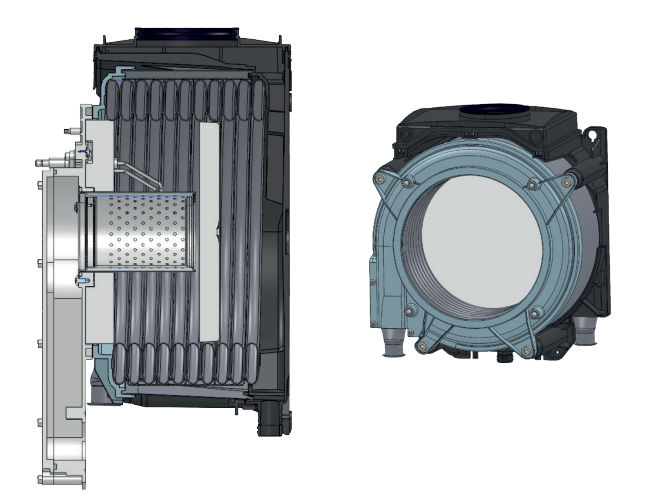

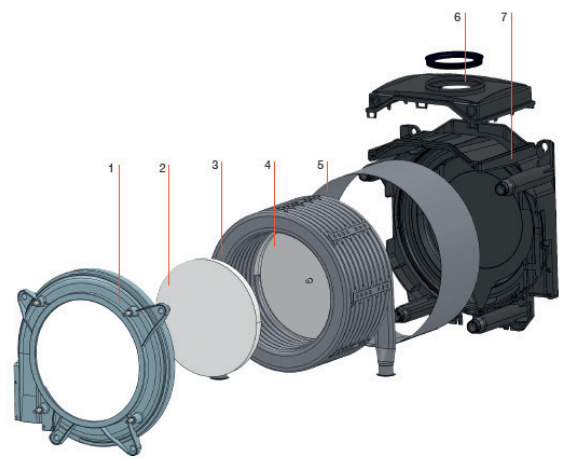

“Circond” is an integrated and compact single-use heat exchanger based on a simple oval stainless steel coil.

The heat exchanger consists of a combustion chamber, a condensing zone and an insulated metal disc protected with silicon ceramic fibre separating the two zones.

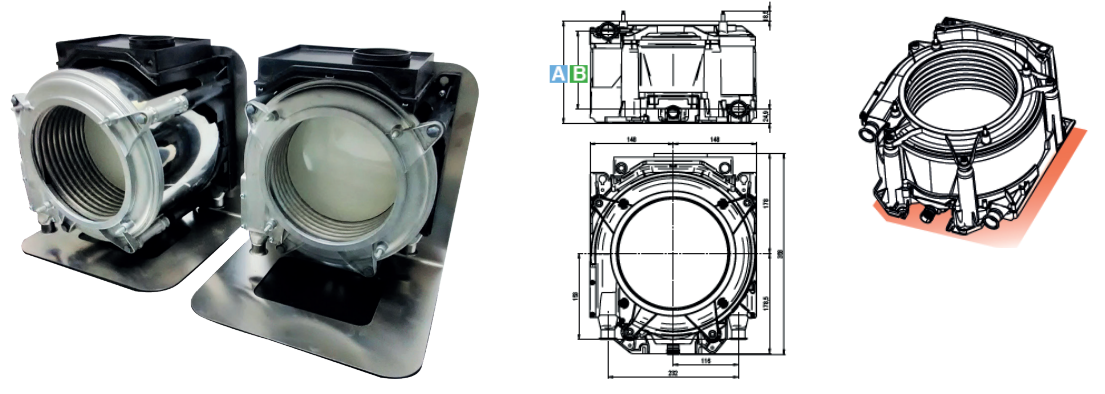

• COMPACT

• EASY INTERCHANGEABILITY

• COMPLETE RANGE FOR DOMESTIC APPLICATIONS

• IMPROVED PERFORMANCE AND HIGH RELIABILITY

• MODULAR FOR DIFFERENT OUTPUTS

ADVANTAGES OF A SINGLE COIL HEAT EXCHANGER:

• SELF-CLEANING

• MINIMUM NUMBER OF COMPONENTS

• HIGH EFFICIENCY AND STRENGTH

• STAINLESS STEEL

• AVOID WELDING PROCESS

FUNCTIONAL PRINCIPLES

• SELF-CLEANING

• MINIMUM NUMBER OF COMPONENTS

• HIGH EFFICIENCY AND STRENGTH

• STAINLESS STEEL

• AVOID WELDING PROCESS

DESIGN FEATURES

The hot flue gas produced in the combustion chamber passes through the first coils before the metal disc and exits to the outer casing realizing the high temperature heat exchange; the flue gas passes through the baffle and passes through the last coils, realizing the low temperature heat exchange that preheats the incoming water through the condensation of the exhaust.

Condensate, produced by the high decrease in flue gas temperature, drains from the bottom of Circond, on the opposite side flue gas exits from the top.

The metal disc separates the combustion chamber from the condensing part, and the position of the disc is variable: this distinctive feature ensures optimized condensation heat exchange for each specific power size.

This particular property affects both the flue gas pressure drop and the amount of condensate produced, consequently the efficiency of the Heat Exchanger.

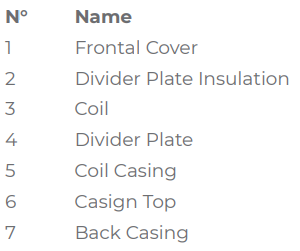

PRODUCT RANGE

The three models differ from each other in the number of coil windings and consequently in the dimensions

outside.

In the figure below, for the same diameter, the depth (A) and the Heights of the spacing of the interaxes of the water fittings change (B)

STRONG RELIABILITY: PRODUCT VALIDATION

CIRCOND HAS PASSED MANY DIFFERENT KINDS OF TESTS AND HAS A SOLID DESIGN CONCEPT:

• CFD ANALYSIS.

• ROBUST DESIGN METHODOLOGY

• IMPROVED EFFICIENCY AND COMBUSTION ANALYSIS

• ACCELERATED LIFE TEST WITH SEVERAL CYCLES RUN UNDER DIFFERENT CRITICAL CONDITIONS

• LARGE FIELD TEST

• CORROSION ANALYSIS

| Heat exchanger model [coils number] | 13.5 | 15.5 | 17.5 |

|---|---|---|---|

| CH input power [BTU] | 85000 | 120000 | 150000 |

| DHW input power [BTU] | 114000 | 150000 | - |

| AFUE Efficiency [%] | 95 | ||

| Certification | |||

| ASME CRM National board approved |

|||

| Dimension | |||

| Width* [inch] | 11.6378 | ||

| Height* [inch] | 14.244 | ||

| Detph* [inch] | 8.7007 | 9.7244 | 10.7086 |

| Water connections [inch] | Ø 0.8897 rapid | ||

| Water connections interaxes [inch] | 9.1338x7.0078 | 9.1338x8.03149 | 9.1338x9.0551 |

| Exhaust gas connection [inch] | Ø 2.3622 or Ø 3.1496 (the position can be customized according to customer needs) |

||

* Dimension of heat exchanger without burner door

Azienda

Via Fiume 6

61030 Lucrezia di Cartoceto (PU)

T +39 0721 8757111

F +39 0721 8757153

info@valmex.it

P. IVA 01469410417

Codice destinatario

fatturazione elettronica Italia: 076Y5YL

Copyright 2023 valmex spa. All rights reserved.