- Azienda

- Innovazione

- Prodotti

- Certificazioni

- News & Exhibition

- Lavora con noi

- Contatti

- Azienda

- Innovazione

- Prodotti

- Certificazioni

- News & Exhibition

- Lavora con noi

- Contatti

Italiano

English

Scambiatore di calore

In acciaio inox

Scambiatore di calore

In acciaio inox

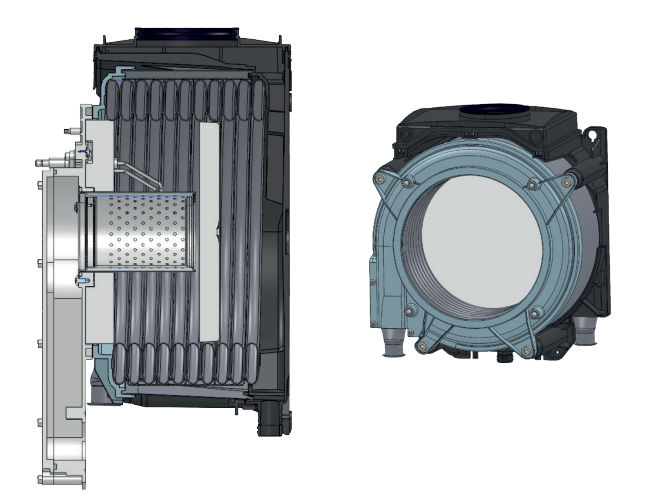

“Circond” è uno scambiatore di calore integrato e compatto basato su una semplice serpentina in acciaio inox a sezione ovale.

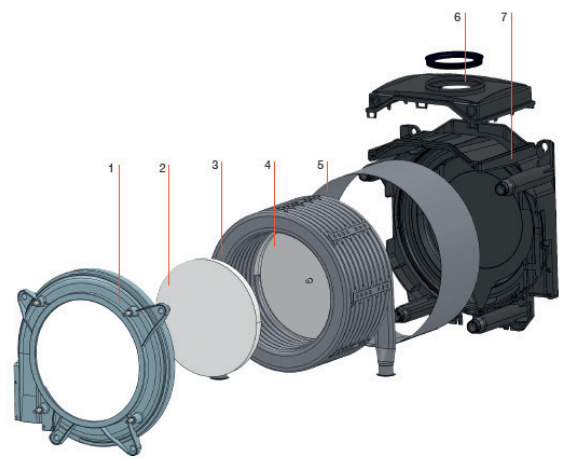

Lo scambiatore di calore è composto da una camera di combustione, una zona condensante e un disco metallico coibentato e protetto con fibra di silicio ceramico che separa le due zone.

• COMPATTO

• FACILE INTERCAMBIABILITÀ

• GAMMA COMPLETA PER APPLICAZIONI DOMESTICHE

• MIGLIORI PRESTAZIONI E ALTA AFFIDABILITÀ

• MODULARE PER OUTPUT DIVERSI

VANTAGGI DI UNO SCAMBIATORE DI CALORE A SPIRA SINGOLA:

• AUTOPULIZIA

• NUMERO MINIMO DI COMPONENTI

• ALTA EFFICIENZA E ROBUSTEZZA

• ACCIAIO INOSSIDABILE

• NESSUN PROCESSO DI SALDATURA

PRINCIPI FUNZIONALI

• AUTOPULIZIA

• NUMERO MINIMO DI COMPONENTI

• ALTA EFFICIENZA E ROBUSTEZZA

• ACCIAIO INOSSIDABILE

• NESSUN PROCESSO DI SALDATURA

DESIGN FEATURES

I fumi caldi prodotti nella camera di combustione attraversano le prime serpentine prima del disco metallico ed escono all’esterno verso l’involucro esterno realizzando lo scambio termico ad alta temperatura; i fumi oltrepassano il deflettore e attraversano le ultime serpentine, realizzando lo scambio termico a bassa temperatura che preriscalda l’acqua in ingresso attraverso la condensazione dello scarico.

La condensa, prodotta dall’elevata diminuzione della temperatura dei fumi di scarico, defluisce dalla parte inferiore di dello scambiatore e dalla parte opposta i fumi escono dall’alto.

Il disco metallico separa la camera di combustione dalla parte condensante e la posizione del disco è variabile: questa caratteristica distintiva garantisce uno scambio termico ottimizzato per ogni specifica taglia di potenza.

Questa particolare proprietà influisce sia sulle perdite di carico dei fumi che sulla quantità di condensa prodotta, di conseguenza sul rendimento dello Scambiatore di Calore.

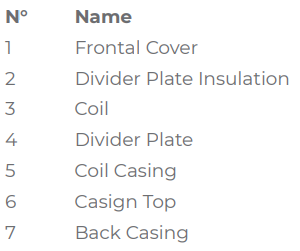

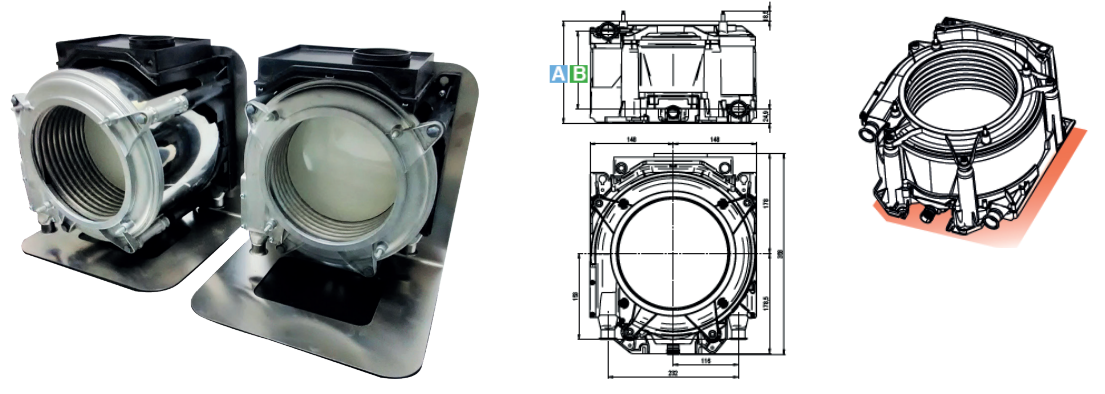

GAMMA DI PRODOTTI

I modelli si differenziano tra loro per il numero degli avvolgimenti delle spire e di conseguenza per le dimensioni

esterne. Nella figura sottostante a parità di diametro cambiano la profondità (A) e le Altezze degli interassi dei raccordi

idrici (B)

FORTE AFFIDABILITÀ: CONVALIDA DEL PRODOTTO

CIRCOND HA SUPERATO DIVERSI TIPI DI TEST E HA UN SOLIDO CONCETTO DI DESIGN:

• ANALISI CFD

• METODOLOGIA DI PROGETTAZIONE ROBUSTA

• MIGLIORE EFFICIENZA

• PROVA VITA ACCELERATA CON DIVERSI CICLI ESEGUITI IN DIVERSE CONDIZIONI CRITICHE

• AFFIDABILITÀ SUL CAMPO

| Modello scambiatore di calore [numero spire] | 8.5 | 10.5 | 11.5 | 13.5 | 15.5 | 17.5 |

|---|---|---|---|---|---|---|

| CH input power [kW] | 21 | 24 | 27 | 28 | 32 | 45 |

| DHW input power [kW] | 24 | 28 | 33 | 35 | 40 | 48 |

| Efficienza [%] | Erp compliant | |||||

| Dimensioni | ||||||

| Larghezza* [mm] | 295.6 | |||||

| Altezza* [mm] | 361.3 | |||||

| Profondità* [mm] | 156 | 182 | 195 | 221 | 247 | 272 |

| Connessioni acqua [mm] | Ø 22.6 rapid | |||||

| Interasse connessioni acqua [mm] | 232x113 | 232x139 | 232x152 | 232x178 | 232x204 | 232x230 |

| Connessione uscita fumi [mm] | Ø 60 or Ø 80 (la posizione può essere personalizzata in base alle esigenze del cliente) |

|||||

* Dimensioni dello scambiatore di calore senza porta bruciatore

Azienda

Via Fiume 6

61030 Lucrezia di Cartoceto (PU)

T +39 0721 8757111

F +39 0721 8757153

info@valmex.it

P. IVA 01469410417

Codice destinatario

fatturazione elettronica Italia: 076Y5YL

Copyright 2023 valmex spa. All rights reserved.